The silos are suitable for the storage of raw materials (semolina, flour) used for the production of dry pasta.

Silo capacity, according to customer requirements.

FEATURES

| • | Silos in stainless steel AISI 304 (parts in contact with the product and insulation) ore painted steel with conical bottom resting on foot. |

| • | Silos with steel support frame and parts in contact with product in Trevira. |

| • | Silos fiberglass. |

SILOS IN PAINTED STEEL

SILOS TREVIRA

SILOS FIBERGLASS

Used to dose continuously and automatically the ingredients on mixers/presses/etc.

FEATURES

| • | Structure in stainless steel AISI 304 and/or 316. |

| • | Dosing screw conveyors in various forms / material depending on the product to be dosed. |

| • | Automatic weighing systems in order to guarantee a weight dosage product. |

DOSING SYSTEMS SEMOLINA, FLOUR

DOSING SYSTEMS FOR MICRO INGREDIENTS

DOSING SYSTEMS FOR MICRO INGREDIENTS

DOSING SYSTEMS + PUMPS FOR LIQUIDS

Used for imbibe in a homogeneous way the semolina / flour with the water / liquid additives.

FEATURES

| • | Structure in stainless steel AISI 304 and/or 316 |

| • | Mixing shaft in single or dual reel (depending on requirements) removable for easy cleaning |

| • | Supports and bearings watertight |

PRE-MIXER

PRE-MIXER

PRE-MIXER

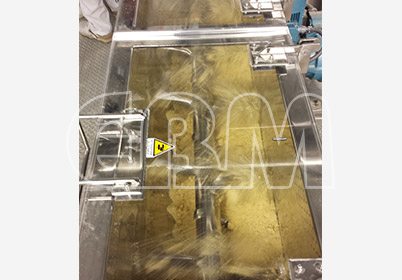

Suitable for kneading deeply and homogeneously, mixtures of semolina/flour/wholemeal flour, etc., with water and / or emulsions.

The mixers can be (optional) with a total vacuum.

FEATURES

| • | Platform with service gangway, access stairs in stainless steel AISI 304 and antislip surface |

| • | Mixer with 1 shaft and/or 2 shaft in stainless steel AISI 304 and/or AISI 316 |

| • | Mixer, shaft, paddles (all in stainless steel AISI 304 or 316) are polished, in order to reduce the adhesion of the dough |

| • | The covers of a thick transparent material are complete with sturdy handles for easy opening |

AUTOMATIC CONTINUOUS MIXERS

AUTOMATIC CONTINUOUS MIXERS

AUTOMATIC CONTINUOUS MIXERS

AUTOMATIC CONTINUOUS MIXERS

Suitable for an industrial production of short cut pasta in a continuous way.

The automatic presses have the characteristic of using technology to "total vacuum".

FEATURES

| • | Platform with service gangway, access stairs in painted steel or in stainless steel AISI 304 and antislip surface |

| • | Mixer “total vacuum” with 1 shaft and/or 2 shaft in stainless steel AISI 304 and/or AISI 316 |

| • | Mixer, shaft, paddles (all in stainless steel AISI 304 or 316) are polished, in order to reduce the adhesion of the dough |

| • | The covers of a thick transparent material are complete with sturdy handles for easy opening |

| • | Compression cylinder/s complete with jacket for cooling water circulation |

| • | Screw/s in in special alloy steel. The screw design, the surface treatment, the low rotation speed have been studied and achieved, in order to reduce to the minimum the heating up of the dough due to mechanical shear |

| • | Head/s fixed with screws and hinges to the cylinder for an easy opening, suitable for round dies |

| • | Head/s fixed with screws to the cylinder, suitable for rectangular dies |

| • | The die extraction takes place with an hydraulic device |

| • | The head/s is equipped with a jacket for cooling water circulation |

| • | The head/s is equipped with a jacket for cooling water circulation |

| • | Electric control panel |

PRESS/EXTRUDER 150 kg/h

Short Cut

PRESS/EXTRUDER 800 kg/h

Short Cut

PRESS/EXTRUDER 1.500 kg/h

Short Cut

PRESS/EXTRUDER 300 kg/h

Long Cut

PRESS/EXTRUDER 600 kg/h

Specialty Lasagna

PRESS/EXTRUDER 600 kg/h

Specialty Cannelloni

Used for dosing, cutting, positioning of the dough into desired shape

FEATURES

| • | Structure in stainless steel AISI 304 |

| • | Roller (sheeted pasta) in stainless steel AISI 304 up to 1200 mm width |

| • | Electric control panel |

CALIBRATORS AND NEST MACHINE

NEST MACHINE

LASAGNA MACHINE

LASAGNA MACHINE

Suitable to pre-dry short-cut pasta, stuffed pasta and similar products.

FEATURES

| • | Structure in stainless steel AISI 304 |

| • | Vibrating levels with edges and net in stainless steel AISI 304, assembled on supports with elastic rods |

| • | Movement to means of eccentric shaft and flywheel, belt drive through motor controlled by an inverter to vary the transit time |

| • | Heating batteries for hot water (on request batteries for steam or heating with electric resistances) |

| • | High power ventilating groups for a good ventilation of the product |

| • | Temperature control system and extracting moisture |

| • | Insulating panels in polyurethan sealed between two plates in stainless steel AISI 304 |

SHAKER PRE-DRYER (Trabatto)

SHAKER PRE-DRYER (Trabatto)

SHAKER PRE-DRYER (Trabatto)

SHAKER PRE-DRYER (Trabatto)

Suitable to pre-dry and dry of short-cut pasta, stuffed pasta, long cut pasta (spaghetti), nest, cannelloni, lasagna and similar products.

FEATURES

| • | Structure in stainless steel AISI 304 |

| • | Short cut pasta: conveyor belts in polypropylene net thermo stable at high temperature of complete support rods in stainless steel fastened to lateral transport chains |

| • | Long cut pasta (spaghetti): special chains with step support for the transport of the sticks. Sticks in stainless steel |

| • | Specialty Pasta: transport trays system containing the product to be dried. Trays in stainless steel |

| • | Movement for conveyor belt, chains or trays by means of geared motors controlled by inverter in order to vary the transit time |

| • | Command and control system of the drying diagram consisting of: - heating system with cooling coils working with hot water; - moist air extracting system ; - high power ventilating groups for a good ventilation of the product; - Temperature control system and extract moist air |

| • | Insulating panels in polyurethan sealed between two plates in stainless steel AISI 304 |

CONTINUOUS DRYERS

CONTINUOUS DRYERS

CONTINUOUS DRYERS

CONTINUOUS DRYERS

CONTINUOUS DRYERS

Suitable to dry of short-cut pasta, stuffed pasta, long cut pasta (spaghetti), nest, cannelloni, lasagna and similar products and similar products.

FEATURES

| • | Structure in stainless steel AISI 304 |

| • | Command and control system of the drying diagram consisting of: - heating system with cooling coils working with hot water; - moist air extracting system; - high power ventilating groups for a good ventilation of the product; |

| • | Temperature control system and extract moist air |

| • | Insulating panels in polyurethan sealed between two plates in stainless steel AISI 304 |

| • | Trolleys for trays made in stainless steel AISI 304. The trolley is mounted on wheels |

| • | Trolleys for sticks made in stainless steel AISI 304. The trolley is mounted on wheels |

DRYING CELL

(2 trays)

DRYING CELL

(4 trays)

LONG CUT PASTA TRAYS

(spaghetti)

DRYING CELL

(8 trays)

DRYING CELL

(8 trays)

CARRELLI PASTA LUNGA

(Spaghetti)

More and more customers are asking "turnkey" supplies with a single company in charge of all ancillaries needed for the production facility operation (Boilers, chillers, cooling towers, etc.).

E.B.M. is specialized in providing these ancillaries in cooperation with leading European manufacturers in order to provide the complete package to the customer.

FEATURES

| • | Boiler for the supply of steam or hot water (60 and /or 90°C). |

| • | Water cooling chillers (5 ÷ 15 ° C) |

| • | Cooling towers for water at 25 ÷ 30 ° C |

| • | Compressed air generators (5 ÷ 10 bar). |

| • | Water treatment systems (industrial and potable) |